Time:2023-05-18 Source: Original Clicks:1759

Waveplates,

also known as retardation plates or phase shifters, are flat optical components

designed to manipulate the polarization state of light waves. They consist of a

birefringent material,which has different refractive indices for different

polarization directions.

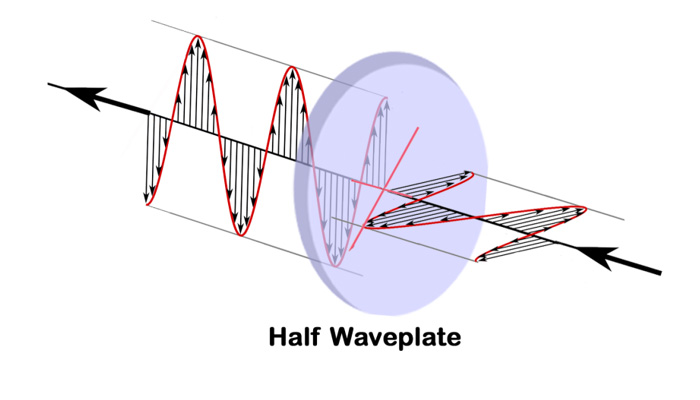

When a polarized light wave enters a waveplate, it splits into two components, called the ordinary ray and the extraordinary ray, each of which travels at a different speed through the birefringent material. As a result, the two rays accumulate a relative phase shift that depends on the thickness and birefringence of the waveplate. Themost common types of waveplates are the quarter-waveplate and the half-waveplate.

A quarter-waveplate introduces a relative phase shift of π/2between the two polarization components, which converts linearly polarized light into circularly polarized light or vice versa.

A

half-waveplate introduces a relative phase shift of π, which rotates the

polarization direction of linearly polarized light by a certain angle.

Waveplates are

widely used in various optical applications, such as polarization control,

interferometry, microscopy,and spectroscopy. They can also be combined with

other optical elements, such as polarizers, lenses, and mirrors, to create more

complex optical systems.

Multiple order and zero order waveplatesare two types of waveplates that differ in their performance characteristics.

Zero

Order: Azero order waveplate is a waveplate that is designed to introduce

a specific phase shift (e.g., π/2 for a quarter-waveplate or π for a

half-waveplate) between the two polarization components of incident light,

without introducing any additional phase shifts. This means that the output

polarization state is purely a function of the input polarization state and the

waveplate's thickness and birefringence. Zero order waveplates are often

preferred in applications where high polarization purity and accuracy are

required, such as inpolarization-sensitive interferometry and polarimetry.

Standard Zero Order: A standard zero order waveplate is made by taking a birefringent material (such as quartz or magnesium fluoride) and cutting it to a specific thickness based on the desired phase shift (e.g., π/2 for a quarter-waveplate).

The thickness

is chosen to ensure that the phase difference between the two polarization

components of the incident light is exactly the desired value, and the

resulting waveplate is called a zero order waveplate. However, due to small

variations in the birefringent material,there can still be a small amount of

unwanted phase shift introduced, which can lead to some degree of polarization

distortion in the output light. This is referred to as residual birefringence.

True Zero

Order: A true zero order waveplate, on the other hand, is made by using a more

precise manufacturing process that minimizes the residual birefringence.One

method to achieve this is to use a birefringent material with a very small birefringence,

such as crystalline quartz, and to cut the material at a specific angle to the

crystal axis. This produces a waveplate with a much smaller residual

birefringence, resulting in a higher degree of polarization purity in the

output light.

Multiple

Order: A multiple order waveplate, on the other hand, is a waveplate that introduces

multiple phase shifts (i.e., integer multiples of the designed phase shift)

between the two polarization components of incident light. This occurs because

the thickness of the waveplate is not an exact multiple of the wavelength of

light, which causes the different wavelength components of the incident light

to accumulate different phase shifts.

Multiple order

waveplates are less expensive to manufacture than zero order waveplates and can

be used in many polarization control applications. However, they have some

drawbacks, including a lower polarization purity and a higher sensitivity to

wavelength and temperature changes.

Achromatic –

Achromatic waveplates consist of two different materials that practically

eliminate chromatic dispersion. Standard achromatic lenses are made from two

types of glass, which are matched to achieve a desired focal length while

minimizing or removing chromatic aberration. Achromatic waveplates operate on

the same basic principle. For example, Achromatic Waveplates are made from

crystal quartz and magnesium fluoride to achieve nearly constant retardation

across abroad spectral band.

Applications:

Lasers Applications:

1.Wavelength

combining and separation:Waveplates are used to manipulate the polarization of

light in laser systems to combine and separate different wavelengths of light. This

is useful in applications such as spectroscopy, where different wavelengths

need to be separated and detected separately, or in telecommunications where

different wavelengths are combined for high-speed data transmission.

2.Q-switching: Waveplates

can be used in Q-switching, a technique used to achieve extremely high pulse

powers in lasers. Q-switching involves rapidly switching the laser cavity from

a low-Q state to a high-Q state, which causes the stored energy to be released

in a short pulse. Waveplates can be used to control the polarization of light

in the cavity, which affects the Q-switching performance and pulse

characteristics.

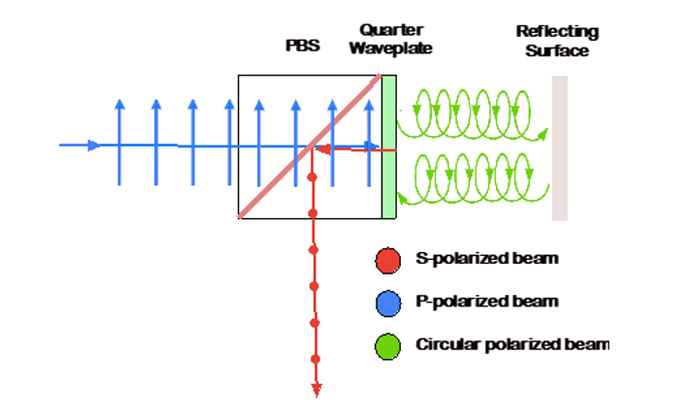

3.Destructive

feedback quenching: In laser systems, destructive feedback can occur when

reflected light interferes with the laser beam and causes damage to the laser.

Waveplates can be used in to create and Optical Isolator to control

the polarization of the reflected light and prevent destructive feedback.

4. Circular

polarization in industrial laser cutting: Circularly polarized light can

be used in industrial laser cutting systems to achieve cleaner and more uniform

cuts. This is because circularly polarized light produces a more symmetric beam

profile and reduces the effects of beam distortion and scattering. Waveplates

can be used to convert linearly polarized light to circularly polarized light

in these systems.

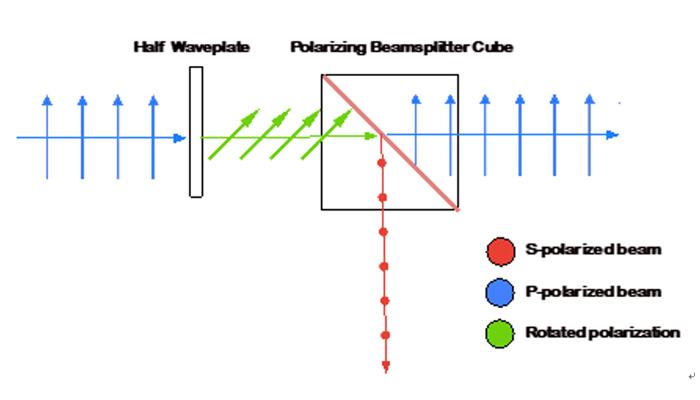

Variable

Beamplitter: Avariable beamsplitter is a device that divides a beam of light

into two separate beams, with the amount of light split between them being

adjustable.It uses a polarizing beamsplitter cube and a half waveplate to

control the transmission (P polarized light) and reflection (S-polarized light)

inside the cube. By rotating the half waveplate, the polarization angle of the

incoming light can be modified, which adjusts the amount of light transmitted

through the beamsplitter versus the amount that is reflected. This provides

precise control over the output ratio of the beamsplitter.

If the

polarization of the two separated beams needs to be aligned on the same plane,

a half waveplate can be inserted into the path ofone of the output beams. By

adjusting the orientation of the waveplate, both beams can be polarized in the

same direction. This is crucial in applications where the beams need to form an

interference pattern, such as in recording a hologram or writing a holographic

diffraction grating.

Polarization

Cleanup: In some optical systems, multiple reflections from mirrors can cause

changes in the polarization state of light. When the plane of polarization of a

beam is aligned with or perpendicular to the plane of a mirror, there is

usually no change in polarization upon reflection. However, if the polarization

direction makes an angle with the plane of incidence,reflections from mirrors,

can cause small phase shifts between the parallel and perpendicular

polarization components. This can result in the reflected wavebeing slightly

elliptically polarized, which can be observed as degraded extinction when a

polarizer is inserted and rotated. To correct for this, a full waveplate can be

inserted and tilted slightly about either its fast orslow axes to adjust the

retardation and cancel out the ellipticity of the reflected wave.

Definitions and

Terminology:

Fast Axis:The

fast axis is the axis along which light travels with the higher velocity or lower

refractive index in a birefringence material. It is also known as

the"extraordinary axis" or "e-axis." Light polarized along

the fast axis will experience less delay or phase shift compared to light

polarized along the slow axis.

Slow Axis:The

slow axis is the axis along which light travels with the lower velocity or higher

refractive index in a birefringence material. It is also known as

the"ordinary axis" or "o-axis." Light polarized along the

slow axis will experience more delay or phase shift compared to light polarized

along the fast axis.

Birefringence: Birefringence

is a phenomenon in optics where a material exhibits different refractive

indices for light waves of different polarization states.This differential

refractive index causes light waves of different polarization states to refract

or bend at different angles as they pass through the material. As a result, a

single incident light wave can be split into two or more waves that propagate

with different velocities and directions, leading to double refraction or the

splitting of a light wave into two or more rays with different paths.

When

unpolarized light passes through a birefringent material, the different

refractive indices for different polarization states cause the incident light

to be separated into its parallel and orthogonal components, leading to the

phenomenon known as birefringent or birefringent interference. This can result

in the generation of interference patterns, or the polarization of light being

modified as it propagates through the birefringent material.

Retardation:Retardation

refers to the phase shift that occurs between the polarization component

projected along the fast axis and the component projected along the slow axis

of a waveplate. It can be specified in units of degrees, waves, or nanometers,

with one full wave of retardation being equivalent to 360°, half wave being

equivalent to 180° and a quarter being equivalent to wave 90°. In waves it

would be, 1λ, λ/2 and λ/4. In nanometers, λ represents the wavelength of light

in nanometers. For example, if the half waveplate is designed for use with

light of wavelength 532 nm, the retardation would be 0.5 * 532 nm = 266nm.

Retardation

values for most waveplates are λ/4, λ/2, and 1λ. However, other values can be

useful a phase shift may occur between optical components caused by an internal

reflection in one of the components. A compensating waveplate can be used to

restore the desired polarization.